As the demand for more efficient energy usage in vehicles and electronic devices continues to rise, traditional lithium-ion batteries are facing limitations. These conventional power sources have reached a plateau in energy density, restricting advancements in electric vehicles and compact technology.

Enter structural batteries, a cutting-edge innovation that combines energy storage with structural functionality. These batteries integrate directly into the architecture of devices, allowing for a reduction in weight and enhanced performance.

The Concept of Structural Batteries

Unlike traditional batteries that are housed separately, structural batteries are embedded within the device or vehicle itself. This integration negates the need for distinct structural and energy systems, leading to significant weight reductions and better efficiency.

For instance, replacing an electric car’s roof with a structural battery could cut its weight by up to 20%. This weight savings could be redirected to include more batteries, thereby extending the vehicle’s range and efficiency without altering its size.

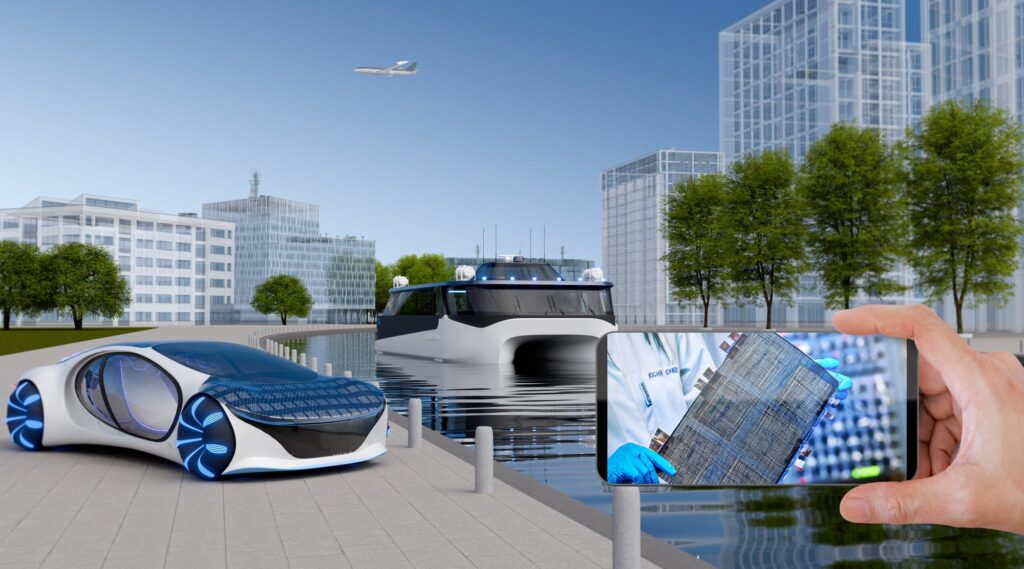

This technology could also revolutionize personal electronics. Laptops could become half as heavy, and smartphones might be reduced to near paper-thin dimensions. Electric vehicles equipped with structural batteries could see a 70% boost in driving range.

“It’s like a human skeleton,” explains Richa Chaudhary, a researcher at Chalmers University of Technology in Sweden. “It carries loads but also performs other vital functions.” This multifunctional design could redefine power and structure in a wide variety of machines.

Materials Driving Innovation

The success of structural batteries hinges on advanced materials like intermediate modulus polyacrylonitrile-based carbon fibers (PAN-CF). These fibers balance mechanical strength with electrochemical capabilities, serving as both electrodes and reinforcing structures.

Research has shown encouraging outcomes when carbon fibers are coated with lithium iron phosphate (LFP) using electrophoretic deposition. However, initial trials indicated a capacity retention of just 47% after 100 cycles due to weak LFP-to-fiber adhesion.

As LFP nanoparticles detach from the carbon fibers with repeated use, performance drops. Incorporating reduced graphene oxide (rGO) has improved adhesion, achieving a specific capacity of 72 mAh g⁻¹ at a 2C-rate, though this is still below theoretical potential.

Further innovations include pairing carbon fibers as the anode with aluminum foil coated in LFP as the cathode. Tests with various separators showed that thinner materials reduced internal resistance, enhancing energy densities. For example, the Whatman GF plain weave separator doubled energy density from 12 Wh/kg to 24 Wh/kg.

Chalmers University of Technology has been a leader in structural battery research since 2018, demonstrating the capability of stiff carbon fibers to store electrical energy.

The latest breakthrough involves a carbon fiber composite battery with an energy density of 30 Wh/kg and an elastic modulus of 70 GPa—matching aluminum in stiffness but at a lighter weight.

Research leader Leif Asp emphasized, “Investing in light and energy-efficient vehicles is a matter of course if we are to economize on energy and think about future generations.” Structural batteries could make electric cars 70% more energy-efficient while adhering to safety standards.

Advancing Towards Commercialization

The transition from research to market is complex but increasingly viable. The Chalmers team has established Sinonus AB to expedite commercialization. Portable electronics, such as ultra-light laptops or credit card-thin smartphones, might first see the benefits. In time, this technology could revolutionize the aerospace and automotive sectors.

However, engineering challenges persist. Shifting from liquid to semi-solid electrolytes is essential for higher power densities and enhanced safety, as semi-solid electrolytes lower fire risks, a significant consideration for commercial use.

Structural batteries offer environmental benefits by eliminating the need for heavy current collectors made of aluminum or copper, reducing material use. Moreover, their design avoids conflict metals like cobalt, often linked to traditional lithium-ion batteries.

Integrating carbon fibers into both electrodes simplifies the structure, further lowering weight. In the anode, the fibers function as reinforcement, current collectors, and active material. In the cathode, they support lithium deposition, eliminating unnecessary components and streamlining production.

Challenges and Future Directions

Despite the progress, obstacles remain. Liquid electrolytes still dominate research, limiting the full potential of structural batteries. Additionally, using carbon fibers solely as negative electrodes or relying on commercial LFP foils for positive electrodes restricts innovation.

Chalmers researchers recently showcased an all-carbon-fiber structural battery using pristine carbon fibers as the anode and LFP-coated fibers as the cathode. Embedded in a biphasic solid-liquid electrolyte system, this design achieved an energy density of 33.4 Wh/kg, with a Young’s modulus of 38 GPa.

Advancements in manufacturing have further increased energy density to 42 Wh/kg while maintaining mechanical strength. These developments highlight the potential for structural batteries to seamlessly integrate into large-scale industrial applications, including in cars, planes, and drones.

Interest in structural batteries is growing globally, particularly in automotive and aerospace industries, which stand to gain the most from lighter, more energy-efficient designs. However, substantial investments in research and production are necessary to meet these sectors’ energy demands.

As Professor Asp envisions, “One can imagine that credit card-thin mobile phones or laptops that weigh half as much as today are the closest in time.” With structural batteries poised to upend the current norms, the aspiration for multifunctional materials that drive our vehicles, power our gadgets, and lessen environmental impact might soon be within reach.

Original Story at www.thebrighterside.news