Kongsberg Maritime introduces innovative methods to transform the transportation and installation of floating offshore wind turbines.

The Norway-based company claims these new solutions will streamline processes from anchor installation to electrical cable pull-in, preparing turbines for energy grid connection.

The floating offshore wind strategy includes four key elements: new vessel designs for anchor installation, a novel turbine towing method, an integrated tensioning concept for mooring lines, and a cutting-edge cable pull-in system.

Kongsberg Maritime highlights two new vessel concepts crucial for large-scale mooring operations.

The anchor handling version, UT 7900 FWIV AH, incorporates a triple cross-tensioning winch system, allowing simultaneous tensioning of three mooring lines while reducing bollard pull requirements. The vessel can pull up to 900 tonnes in a single-fall configuration, enhancing anchor handling efficiency and reducing energy use.

“This vessel offers a new approach, featuring additional rope and chain storage for high-volume operations. It ensures safe deployment in a controlled environment,” stated Gunnar Thorsen, Senior Vice President of Business Concepts at Kongsberg Maritime.

The subsea construction vessel, UT 7600 FWIV Subsea, is designed with advanced systems for handling mooring elements.

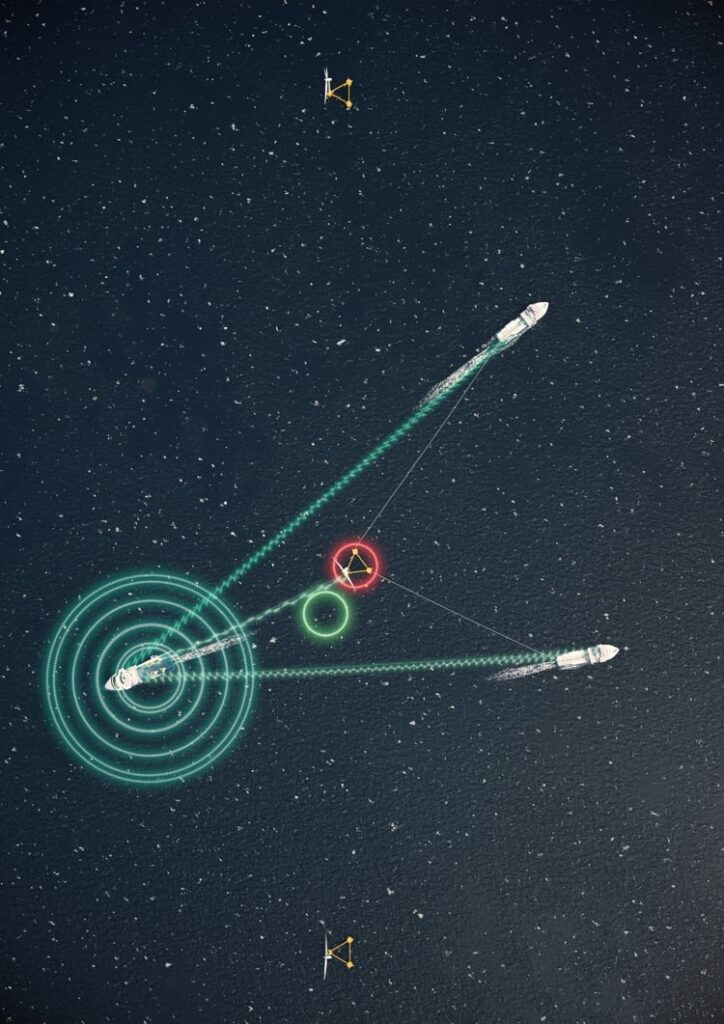

For transporting large turbines to offshore sites, Kongsberg Maritime developed Tow Assist. This solution enhances unpowered floating structures with dynamic positioning capabilities, optimizing vessel performance during complex towing operations.

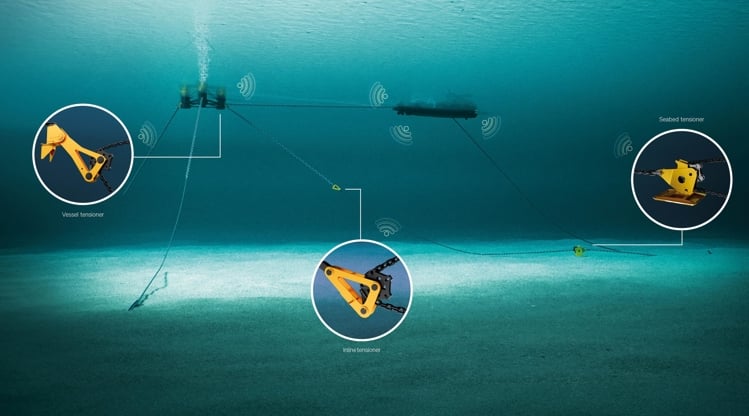

The Integrated Tensioning Concept aims to improve mooring line hook-up operations, compensating for movement between the floater and vessel, thus expanding the operational weather window and ensuring smoother processes.

This concept uses Kongsberg Maritime’s PM winches, recognized for high torque and dynamic capabilities.

“The Integrated Tensioning Concept monitors floater motion, allowing the vessel winch to compensate, reducing peak loads. This ensures smoother hook-ups and extends operational weather conditions,” said Runar Hjelle, Sales Director Offshore Construction & Support at Kongsberg Maritime.

A new cable pull-in method is key in Kongsberg Maritime’s process, requiring less equipment and manpower, enhancing safety, and accelerating wind farm installation.

“Our patented method places all equipment on the vessel, reducing complexity and risk. It enhances safety by minimizing personnel on the floater during pull-in operations,” noted Thorsen.

“Minimized equipment lifting and personnel transfer enables operations in harsher weather, crucial for year-round productivity and faster wind farm installation.”

Follow offshoreWIND.biz on:

Original Story at www.offshorewind.biz